Sponsored article

Technologies in the production of conveyor belts – how BELTA machines shape the transport industry

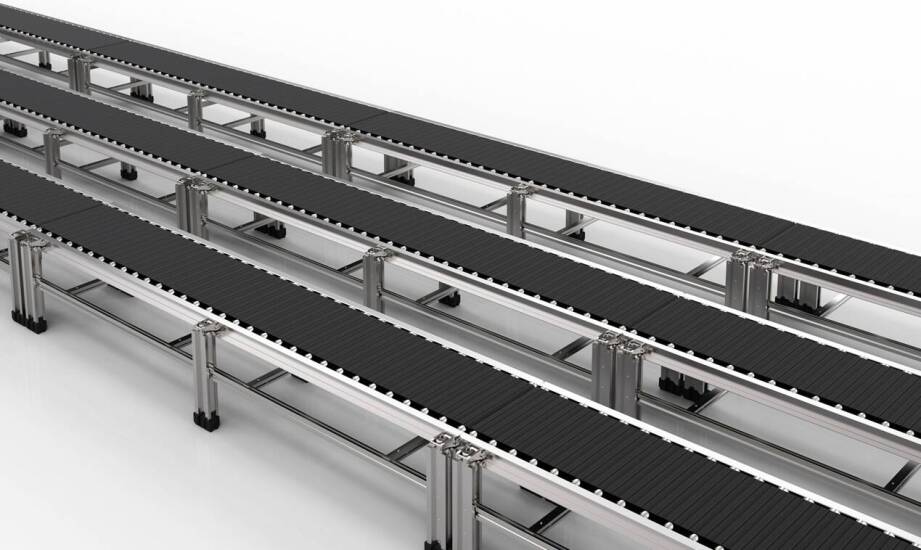

The production of conveyor belts is a key element in many industries. The process requires precision and the use of modern technologies that ensure the durability and functionality of the finished products. BELTA machines enable the production of various belts made of polyvinyl chloride (PVC) and polyurethane (PU). BELTA high frequency welders allow for precise welding of elements such as lifters or side waves, which is crucial for the quality of conveyor belts.

BELTA machines are equipped with systems that monitor welding parameters, which minimises the risk of material damage. The manufacturer can be sure that each belt meets the highest quality standards, regardless of the complexity of the project.

Customisation and flexibility in production

One of the most important aspects of the production of conveyor belts is the possibility of customisation. BELTA machines offer an easy electrode change system, which allows for quick adaptation of the machine to different types of belts. The lifters, T-profiles and guide bars are welded with high precision, ensuring a permanent joint with the base belt. High frequency technology guarantees even heating of the material, resulting in higher quality and durability of the finished products.

Depending on the order additional improvements can be made, such as specialised positioners to facilitate material placement or scales on the work table, which significantly speeds up the production process. Customisation also includes the use of a variety of accessories tailored to the requirements of a given industry.

Advanced technologies to support complex projects

The Zemat Technology Group supplies machines that allow to carry out even the most complex projects. The production of conveyor belts on these machines includes not only standard conveyor belts, but also complex constructions. Each stage of production, from cutting the raw material to the final welding of the elements, is monitored to ensure high quality and reliability.

Advanced control systems, including an intuitive touch panel, allow operators to easily manage the production process, and modern safety systems protect the material from damage. The versatility of BELTA machines allows the production of belts with a complex structure with various types of profiles and accessories, making them an ideal solution for companies in many industries.